Choosing the Right Salt Type for Your Softener

The Wrong Salt Can Destroy Your Water Softener

Not all salt is suitable for water softeners. Some types can quietly cause internal damage, shorten the life of your machine, and even void your warranty.

We regularly find that softeners running on sea and lake salt experience the following problems :

- Sea-type foam and brine cabinet scum (This is a living organism that comes from seaweed)

- Grit and sand in cabinets (which get sucked up by the brine valve and then scratch surfaces of the valve, creating permanent damage)

- Oily residue coating internal parts (which comes from oil and diesel from ships)

Once these contaminants enter the resin cylinder, they are almost impossible to remove. All caused by using the wrong type or wrong grade of salt.

Let’s make sure that doesn’t happen to yours.

What Type of Salt SHOULD You Be Using?

There are several types of salt sold in the UK. Some are ideal for softeners. Others should never go near one.

I have created this short video to explain the difference:

The Four Main Types of Softener Salt

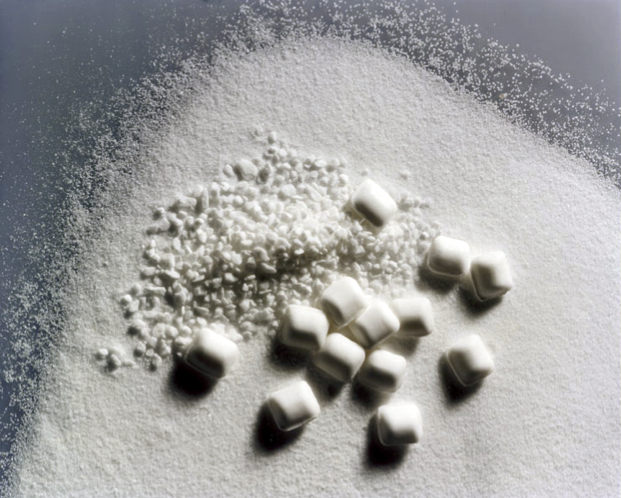

These are the common salts people put into softeners:

-

Block Salt – Best for block salt softeners (we recommend only Harvey Salt and Kinetico Salt.)

-

Tablet Salt – Suitable for most single-cylinder softeners

-

Granular Salt – Not recommended

-

Fine/Table Salt – Never use

Let’s look at why.

Why Granular Salt Causes Damage

Granular salt used to be common, but we now understand the damage it causes.

Fine granules can be drawn into the brine valve and dragged across internal parts, causing scoring on plastic and metal surfaces. Once that happens, seals can no longer do their job — and the softener begins to fail.

Laurence Willis, CEO of Hydroworks:

“I started noticing valve scoring early in my career. Fine salt particles were being pulled through the brine system and damaging components. Once seals are scratched, performance drops and breakdowns follow.”

That’s why we stopped selling granular salt in 2016.

Never Use Table Salt in a Water Softener

Table salt is even finer than granular salt. It is easily sucked into the valve system and can rapidly damage seals, pistons and internal parts.

If it’s small enough to go in a salt shaker — it’s too small for your softener.

WHAT TO DO IF YOU’VE USED THE WRONG SALT

Don’t panic — but do act.

We recommend:

-

Emptying and washing out the cabinet

-

Cleaning and checking the valve is not damaged, resiliconing to help restore seal effectiveness

-

Replacing worn seals if needed

-

Refilling with the correct salt

👉 Hydroworks offer a FREE Softener Health Check if you’d like us to assess it for you.

The Story Behind Block Salt

In the mid-1990s, Harvey Bowden of Harvey Softeners (then trading as Kinetico) adapted the American twin-cylinder, non-electric softener for the UK market. Customers loved these compact machines, but topping them up with loose salt was still messy and inconvenient.

The breakthrough idea came over dinner with his close friend, Geoff, who suggested creating solid salt blocks — similar in concept to animal salt licks. Harvey immediately saw the potential. Although the idea couldn’t be patented because similar products already existed in agriculture, that didn’t stop him. He went on to develop larger, food-grade salt blocks specifically for water softeners.

When block salt first launched, it was sold in simple cardboard packaging. Only one of those original packs survived — and we were proud to present it back to Harvey a few years ago as a thank-you for his support and contribution to the industry.

At the time, some traditional softener manufacturers tried to discourage customers from switching, suggesting that block salt prices would rise sharply once people were committed to block salt machines. In reality, the opposite happened. Harvey worked hard to keep pricing stable, and block salt has remained competitively priced despite wider changes in the salt market.

Today, block salt is widely recognised as one of the cleanest, most convenient ways to keep the right type of softener running efficiently.

Salt Quality Matters - Just as Much as Salt Type

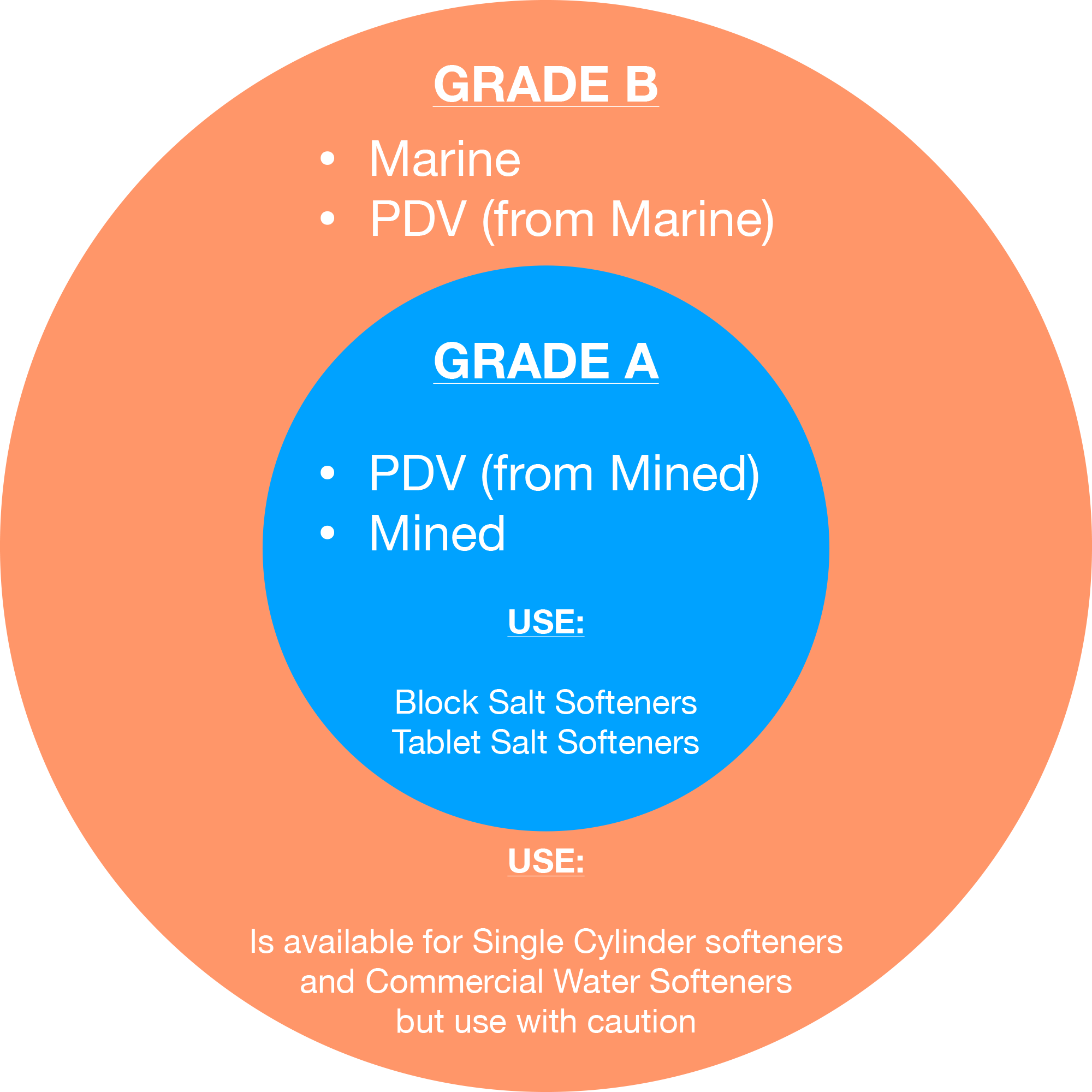

Not all block or tablet salt is equal. Water softener salt is graded by purity.

✅ Grade A (Best Choice)

-

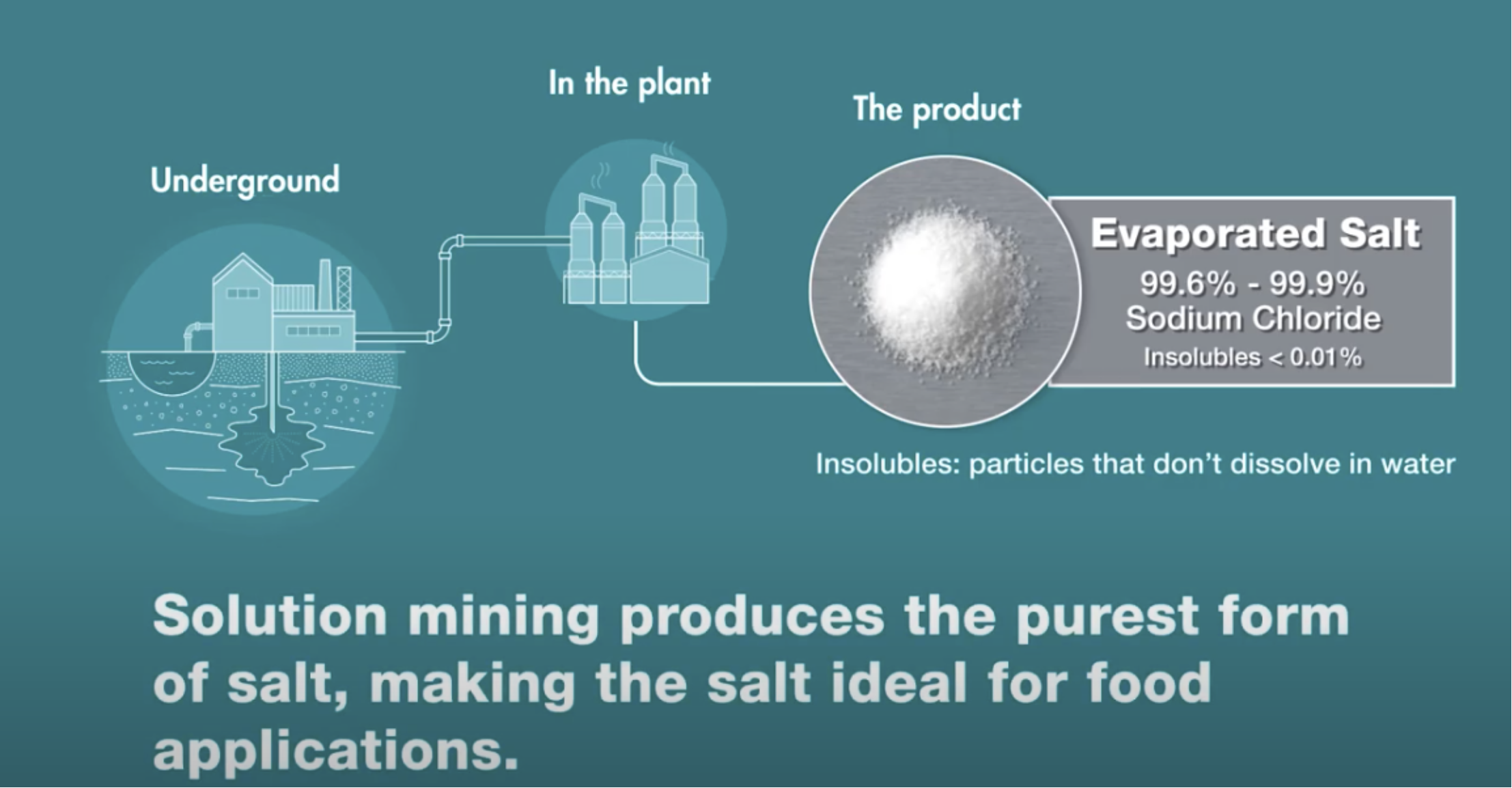

PDV (Pure Dried Vacuum) or high-quality mined salt

-

99.6–99.9% sodium chloride

-

Very low insoluble content

-

Protects your softener and extends lifespan

⚠️ Grade B (Use With Caution)

-

Often marine/sea salt based

-

Contains more impurities

-

Can form scum and residue in brine tanks

-

May increase maintenance

-

Will void warranties in most brands

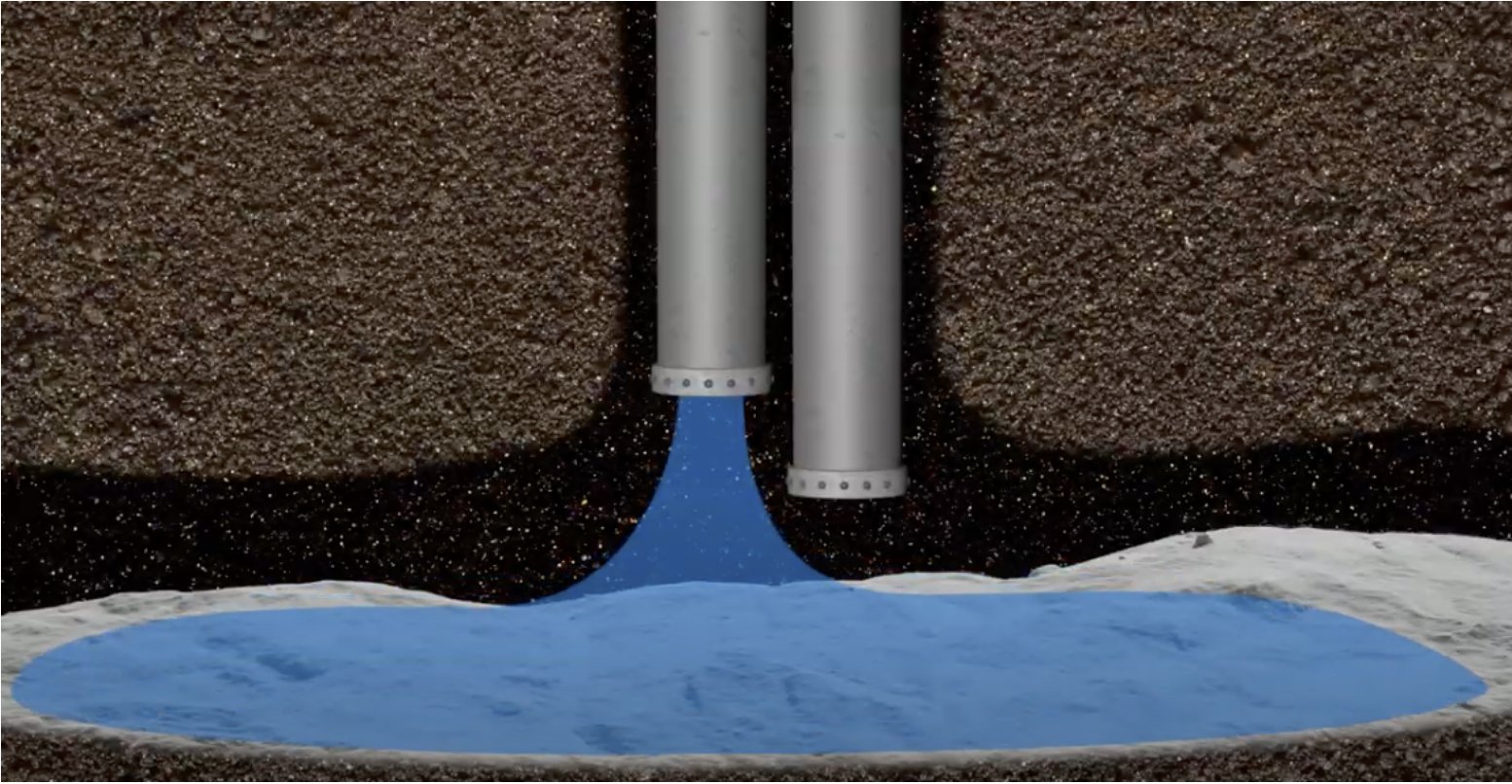

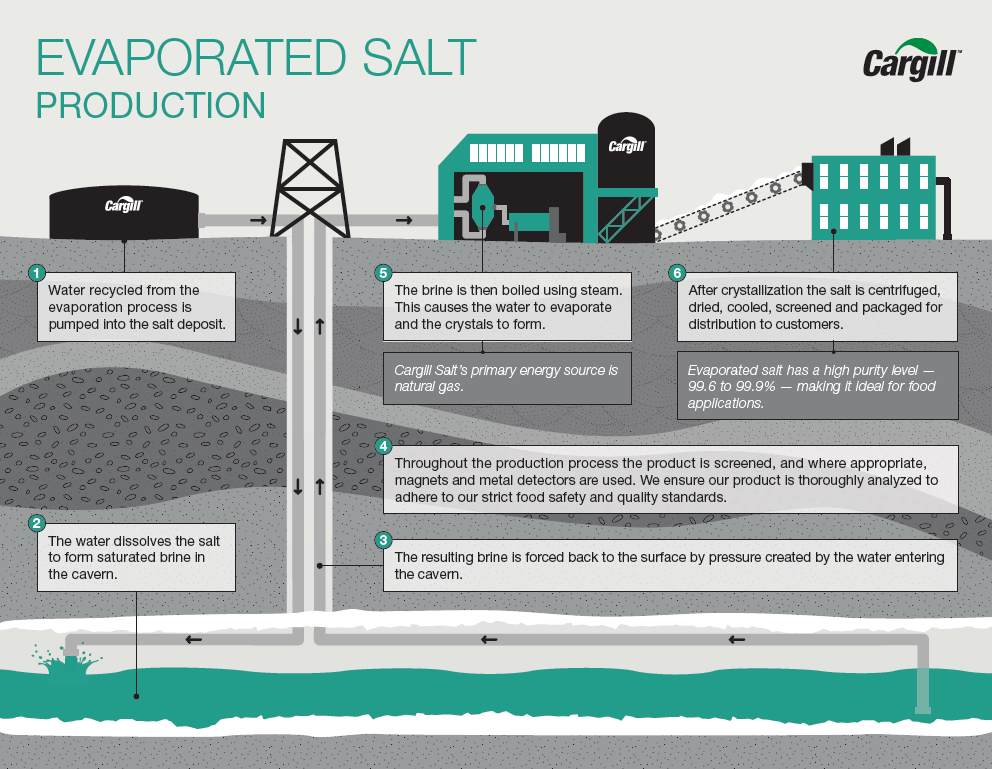

How Grade A PDV Salt is Manufactured

-

Brine created from underground salt

-

Evaporation in controlled evaporators

-

Crystallisation into high-purity salt

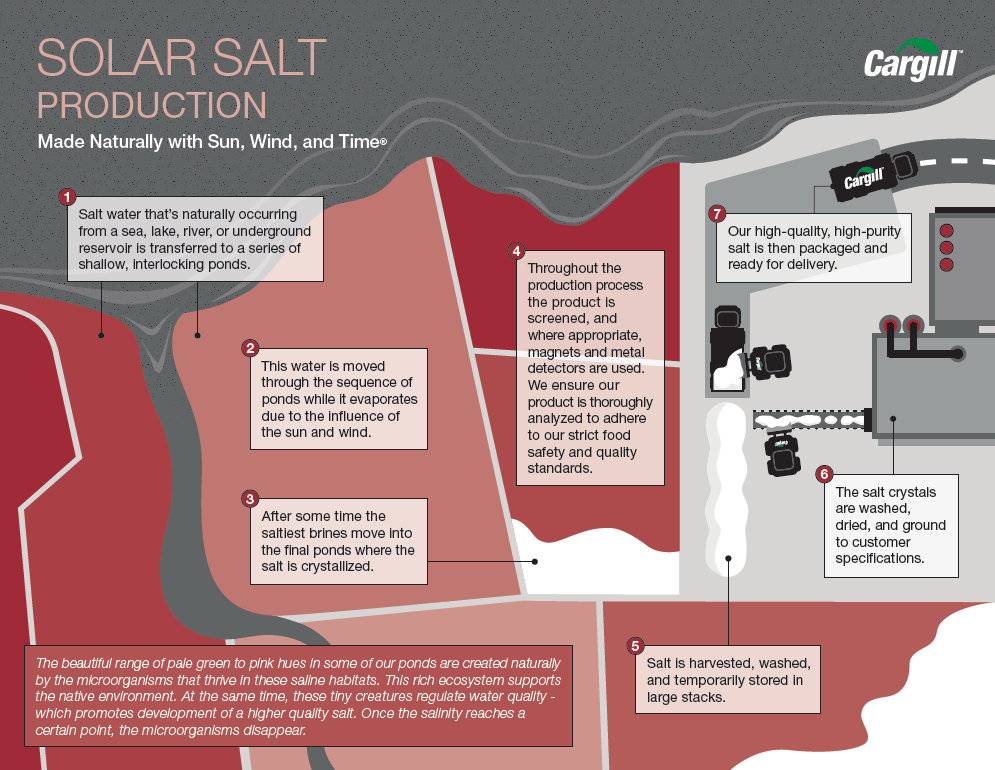

GRADE B - Why Sea and Lake Salt Contains More Impurities

Marine salt is evaporated using sun and wind. While natural, it can contain:

-

Organic material

-

Sediment

-

Trace contaminants

These can create foam, scum and residue in softeners.

-

-

Marine salt is not as clean because it has sand and other contaminants.

Marine salt is not as clean because it has sand and other contaminants.

Important Warranty Warning

Some manufacturers have made their position clear:Some manufacturers have made their position clear:

• Harvey Softeners and Kinetico are among those manufacturers that state that using lower-grade salt can invalidate warranties

• Their machines rely on very clean brine • Impurities can cause blockages and internal wear

Always check your manufacturer’s guidance.

Tablet Salt for softeners

Many single-cylinder softener manufacturers have historically given limited guidance on specific salt types. In our experience, good-quality Grade A tablet salt performs reliably in the vast majority of these systems and helps maintain consistent softener performance.

As water softeners have grown in popularity across the UK and Europe, more salt products have entered the market. Unfortunately, not all of them meet the same quality standards. Lower-grade salts can contain higher levels of impurities, which may increase maintenance needs over time. Choosing a reputable, high-purity product makes a real difference to the long-term health of your softener.

Tablet salt is available in both 10kg easy-lift bags and 25kg bags. The smaller bags usually cost slightly more per kilo, but many customers find the lighter weight far more convenient to handle and store.

In summary:

-

Suitable for single-cylinder softeners

-

Available in 10kg and 25kg bags

-

Always choose high-purity Grade A salt

Block Salt for softeners

Water softener block salt is available in two main sizes: 8kg standard blocks and 4.3kg curved blocks.Water softener block salt is available in two main sizes: 8kg standard blocks and 4.3kg curved blocks.

The traditional 8kg blocks are designed for older model block salt softeners, including many Kinetico systems. The newer 4.3kg curved blocks were developed primarily for more recent Harvey models such as the Harvey Arc, Minimax Innova and TwinTec Cobalt (S5).

Kilo for kilo, straight and curved blocks are typically similarly priced — the main difference is weight, shape, and handling.

Harvey introduced the curved block in response to customer demand for a lighter, easier-to-handle option. At the same time, it allowed them to take tighter control over salt quality and consistency. The curved design also helps the blocks sit and dissolve evenly, supporting reliable brine production.

As lower-quality block salts have entered the UK market in recent years, consistency and purity have become more important than ever. Using the correct, high-quality block salt helps protect the softener’s internal components and maintain long-term performance.

In some cases, curved blocks can also be used in older block salt machines (including certain Kinetico models), giving customers the option of a lighter, more manageable pack — but it’s always best to check compatibility first.

At a glance:

• 8kg blocks – for many older block salt softeners

• 4.3kg curved blocks – for newer Harvey-designed models

• Designed with convenience and purity in mind

• Curved shape helps support consistent, clean brine production

Shop for water softener salt at the best prices

Not Sure What Salt You Should Be Using?

We’re happy to help.

Hydroworks offer a FREE Softener Health Check and can advise you on:

-

The right salt for your machine

-

Whether your softener has been affected

-

How to extend its life

👉 Book your free check here